SUVLA WINES / ESTATES

Our WINERY

Our WINERY

The determination to achieve consistent success as a winery is based on the painstaking approach taken in the vineyards. The winery employs methods that respect the environment and promote bio-diversity, ensuring the health of the vineyards for future generations and continues to innovate using best industry practices and wine-making techniques.

“Fermentation may have been a greater discovery than fire.”

The life cycle of grapes… Transforming in to wine

Suvla pursues to produce wines of subtle, rich in character with elegant and exquisite finish to complement extensive range of dishes. Suvla crafts wines in her unique style to offer a wealth of experience from the grapes of family vineyard Bozokbağ, vineyards of closer circle from North Aegean & Thrace and selected vineyards from Turkey for indigenous varieties, such as, Tokat, Elazığ, Diyarbakır and Cappadocia. These wines reveal its spectacular geography and a land full of history.

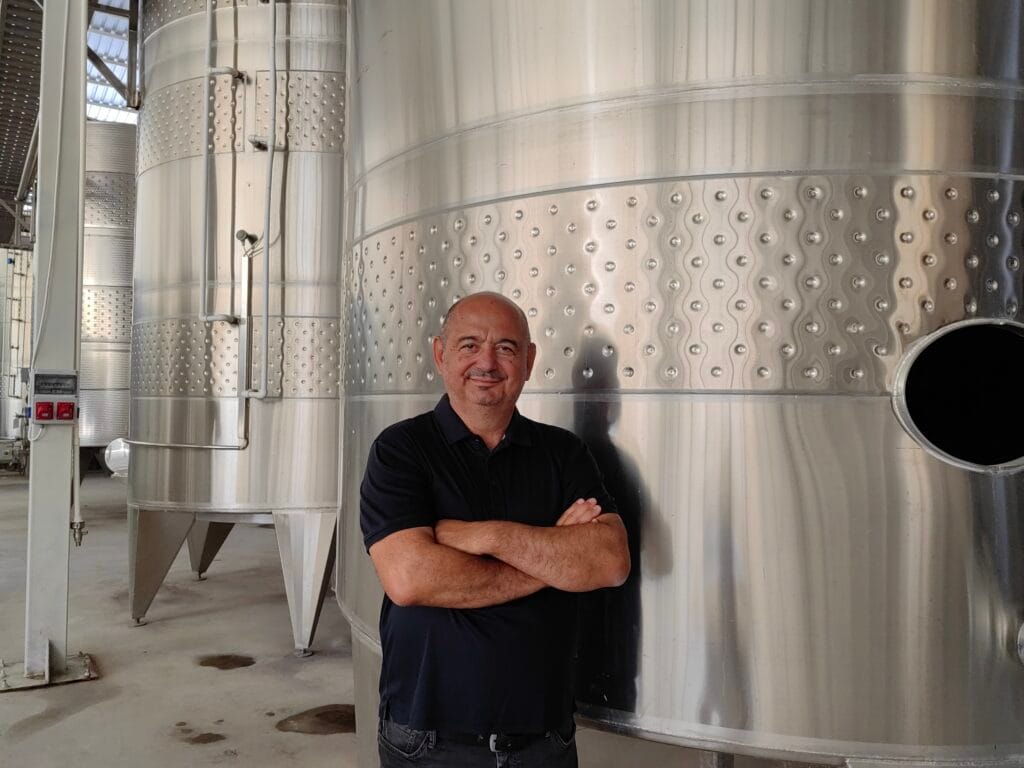

The determination to achieve consistent success as a winery is based on the painstaking approach taken in the vineyards. The winery plays a crucial role to make possible to obtain ultimate quality chateu style wines. Suvla winemakers team and cellarpersons follow up the hard work done in the vineyards by adapting an equally attitude in the cellars. Focusing on quality, working with leaders in all equipments and with latest technologies, winery processes incorporating state-of-the art technology and knowhow.

The winery employs methods that respect the environment and promote bio-diversity, ensuring the health of the vineyards for future generations and continues to innovate using best industry practices and wine- making techniques. The infrastructure of the winery includes 2 wineries both microvinification focused and state of the art technological growth for effective production with a processing capacity of 5 million liters. The wines are crafted by the winemaking team leaded by consultants from France; Bordeaux and Val de Loir. The wines are produced by harvesting local grapes as well as international grapes from their own lands throughout Türkiye separately processing many small private vineyards and local grape varieties especially Kınalı Yapıncak and Karasakız, the local grapes of the North Aegean and Eceabat regions and organic plots which belongs the winery’s terroir.

After harvest, the grapes are held in cool rooms for a short period of time before being processed. The winery layout is configured to process the grapes with gravity. Temperature controlled feature state-of-the art fermentation equipment ensure precise control of the must as well as modern maturation vessels ensure optimum aging. Cooling system and cool rooms enable to retain the aromas and preserve the sugar levels. Rotative fermentation tanks are innovative for the winemakers to increase the the touching capacity between grape must and cap, the tannin and anthocyan can be macerated at the maximum. Stabilization infrastructure helps the winemakers to preserve intense color and the primarily aromas coming from the grapes. Selected wines are aged in French oak barrels for premium and limited edition labels.

The modern style winery houses a facility of traditional olive oil mill for producing extra virgin olive oil as well as processing olive and natural agricultural products.

Suvla kept consumer sensitivity and priorities at the forefront in wine production; conviviality in nature and environmental sustainability along Renewable Solar Energy, Wastewater Management and Organic Viticulture Approach.

As of 2021, the winery switches completely to ‘Renewable Solar Energy’. It carries out the ‘Renewable Energy’ project with great pride in the field of ‘Environmental Sustainability’, focusing on combating changing climate conditions and global warming. The winery and production complex begins to get all its energy from the sun by covering the entire winery roof with solar energy panels. Approximately 71% of the total electrical energy consumption is provided by solar panels. In this way, annually, 2174 trees are saved, 333,490 tons of carbon emissions are reduced.

Another important environmentally friendly investment of the winery is the value it attaches to Wastewater Management. The wastewater generated after processing is purified by removing the polluting elements of the water, preserving its various chemical, physical, bacteriological and ecological properties and making it harmless to nature and the environment. The purification process is carried out by chemical, physical or biological means in the treatment facility with a capacity of 100 tons/day, which includes all the processes. Processes include preliminary sedimentation pool, chemical and biological treatment units, aeration pool, final sedimentation pool, sludge dewatering (filterpress) units. As a result of treatment, wastewater is rendered suitable for the parameters of the receiving environment into which it is discharged and does not change its physical, chemical, bacteriological and ecological properties.

Lately the winery processed around 3500 ton of grape at the harvest of 2023 and 2650 ton at 2024. Suvla Wines have young premium, premium and ultra premium labels to satisfy different tastes. Around 70+ labels of whites, roses and reds are made by the winemaking team.