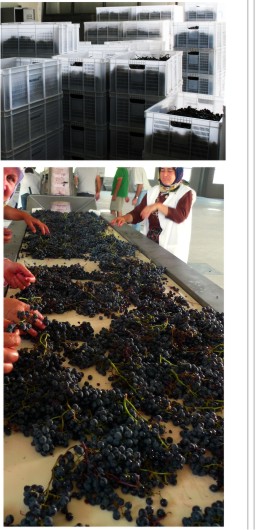

Transformation of fruit in to wine... The making of exquisite wine with the experienced hands of a winemaker

Established in 2009, the modern style winery boasts 5200 square meters and houses a facility of traditional olive oil mill for producing extra virgin olive oil as well as processing olive and natural agricultural products. The determination to achieve consistent success as a winery is based on the painstaking approach taken in the vineyards. The wineryplays a crucial role to make possible to obtain ultimate quality chateu style wines. Suvla winemakers team and cellarpersons follow up the hard work done in the vineyards by adapting an equally attitude in the cellars. Focusing on quality, working with leaders in all equipments and with latest technologies, winery processes incorporating state-of-the art technology and knowhow.

As of 2021, the winery switches completely to 'Renewable Solar Energy'. It carries out the 'Renewable Energy' project with great pride in the field of 'Environmental Sustainability', focusing on combating changing climate conditions and global warming. The winery and production complex begins to get all its energy from the sun. Approximately 71% of the total electrical energy consumption is provided by solar panels. In this way, 2174 trees are saved annually and 333,490 tons of carbon emissions are prevented annually.

Another important environmentally friendly investment of the winery is the value it attaches to wastewater management. The wastewater generated after processing is purified by removing the polluting elements of the water, preserving its various chemical, physical, bacteriological and ecological properties and making it harmless to nature and the environment. The purification process is carried out by chemical, physical or biological means in the treatment facility with a capacity of 100 tons/day, which includes all the processes. Processes include preliminary sedimentation pool, chemical and biological treatment units, aeration pool, final sedimentation pool, sludge dewatering (filterpress) units. As a result of treatment, wastewater is rendered suitable for the parameters of the receiving environment into which it is discharged and does not change its physical, chemical, bacteriological and ecological properties.

After harvest, the grapes are held in cool rooms for a short period of time before being processed. With around 5 million bottling capacity Suvla winery layout is configured to process the grapes with gravity. Temperature controlled feature state-of-the art fermentation equipment ensure precise control of the must as well as modern maturation vessels ensure optimum aging. Cooling system and cool rooms enable to retain the aromas and preserve the sugar levels. Stabilization infrastructure helps the winemakers to preserve intense color and the primarily aromas coming from the grapes. Selected wines are aged in French oak barrels for premium labels.

Lately the winery processed around 3500 ton of grape at the harvest of 2023. Suvla Wines have young premium, premium and ultra premium labels to satisfy different tastes. Around 70 labels of whites, roses and reds are made by the winemaking team.

Suvla Winery strives to improve the viticulture in the region and build up comprehensive valuable alliances with the neighbouring vineyards.

.